I did some research

I want to make my own wet blaster, so I did some research to find out what parts I need.

It’s called a Vapor Blaster in the US, I guess.

Necessary discharge volume

According to Vapor Horning Technologies, Inc., a nozzle with a 10mm inner diameter needs to be able to cover 20CFM = 566L/Min to maintain 50-60psi.

For personal use in the garage, a 5 horsepower air compressor is recommended. It can be roughly calculated as about 3-4 CFM per horsepower.

Nozzle diameter and required size of air compressor

By reducing the nozzle diameter, a smaller air compressor can be used.

| Nozzle diameter | Nozzle cross-sectional area | Ratio | Discharge volume | Size |

|---|---|---|---|---|

| 10mm | 25π㎟ | 100% | 20.0CFM / 566LM | 5HP |

| 8mm | 16π㎟ | 64% | 12.8CFM / 362LM | 3HP |

| 6mm | 9π㎟ | 36% | 7.2CFM / 204LM | 2HP |

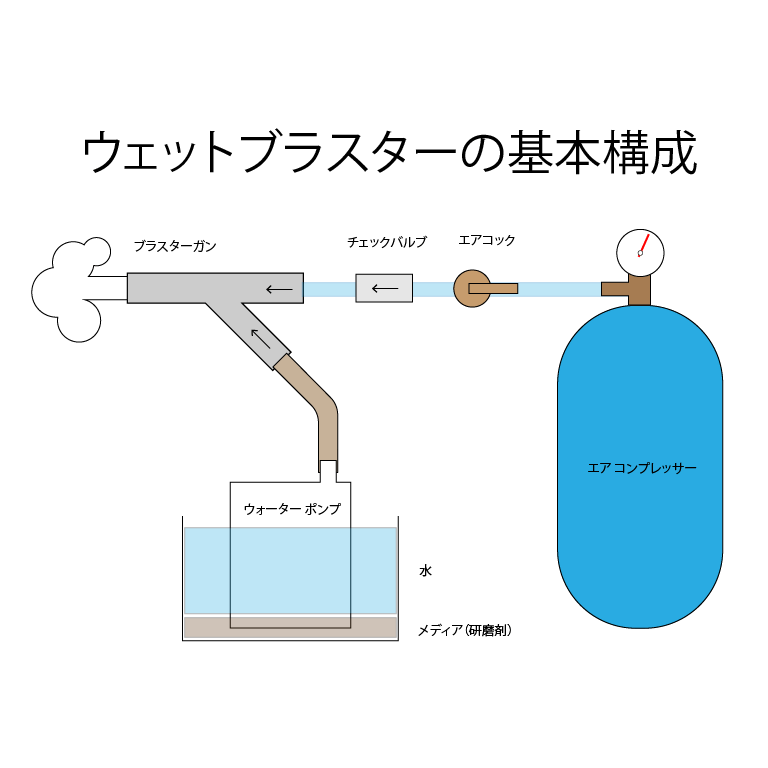

Basic Setup

Minimum required parts

- Blaster gun

- Air cock

- Air compressor 2HP or more

- Water pump 1.5HP or more

- Bottom bucket

- Media (abrasives, alumina, glass beads, etc.)

- Pressure-resistant hose

For the time being, I’ll use a clothing case or something for the blaster cabinet.

The water pump is about 1.5 horsepower, 1100w.

Bonus

The output of the air compressor required for air tools is

- Nailer 2CFM

- Impact wrench 3/8 3CFM

- Impact wrench 1/2 4cFM

The output of the air compressor required for painting is

- 12CFM 70PSI

I want an air compressor with about 3HP.

Oil-free is suitable for painting, but it has a small number of bulbs and is quite expensive.

I’ll try 2HP for now